Augers are not a new invention. In fact, they date back to the Third Century BC when Archimedes of Syracuse (c. 287 – c. 212 BC) invented a positive displacement pump designed to propel water from the bilge of ships. This is the Archimedes Screw. From this simplistic beginning, auger manufacturing has grown to become a thriving industry.

Auger/Screws

Confusion reigns concerning the terms auger and screw. Both refer to various devices and tools. An auger can cut or drill into wood e.g. drill bit. It is also a spiral-shaped tool used to move both solids and liquids from one place to another.

A screw is a sharp-pointed metal device with raised threads running around it. Screwdrivers combine with screws to pierce wood or other materials. This holds boards and other items together. A screw is also a synonym for an auger.

In all cases, one major similarity exists. These devices all possess a spiral to help them accomplish their task. For auger manufacturers, the spiral shape is essential to move the material from the entry point to its destination. For augers of all types, it is about the rotation.

Auger Manufacturing: Basic Auger/Screw Conveyors

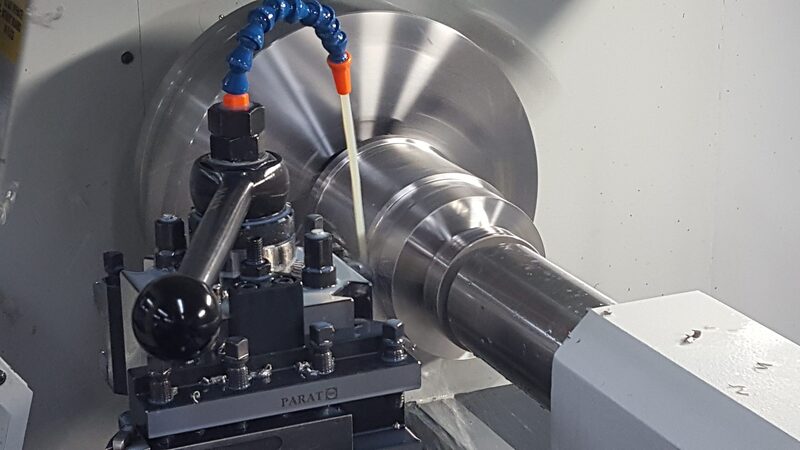

Auger or screw conveyors or simply augers are mechanisms utilizing the screw blade (the flighting) in combination with other components to accomplish the task of moving the designated material. Augers traditionally consist of two parts:

1. The screw blade – helical and rotating

2. Trough or tube

Depending upon the construction, the model may feature a shaft around which the screw blade coils or be shaftless. The set up may be horizontal, at a slight incline or even vertical to move a variety of usually semi-solid substances including:

* Aggregates

* Animal feed

* Boiler ash

* Cereal grains

* Food waste

* Meat and bone meal

* Municipal solid waste

* Wood chips

Auger manufacturers may address all applications or specialize in providing custom-made augers. Before selecting one type of auger and manufacturer over another, do your research.