As an Original Equipment Manufacturer, contract manufacturing company, fabricator or as a machine shop of product development service, working with the best aluminum suppliers has its benefits.

Unfortunately, many companies don’t realize or don’t take the time to compare what different suppliers offer or how their current supplier stacks up against other competitors in the market.

It is easy to get in a rut and just stick with the current supplier. It is also common to avoid looking around and finding out what other suppliers to your industry or to other industries are doing to add value to the materials they offer.

These are a few of the mistakes that Original Equipment Manufacturers and others make when choosing from aluminum suppliers. There are several others that may end up costing you money or reducing the value-added services you could be utilizing.

Shopping on Price Alone

Looking only at the price of the aluminum required for a project or on an ongoing basis is only one part of the picture when comparing and selecting aluminum suppliers.

The top suppliers are competitive in their pricing for most of the aluminum plate, bar and specialty products they offer. Sellers offering low prices may be selling aluminum that is not in top conditions, or that is not produced to quality standards.

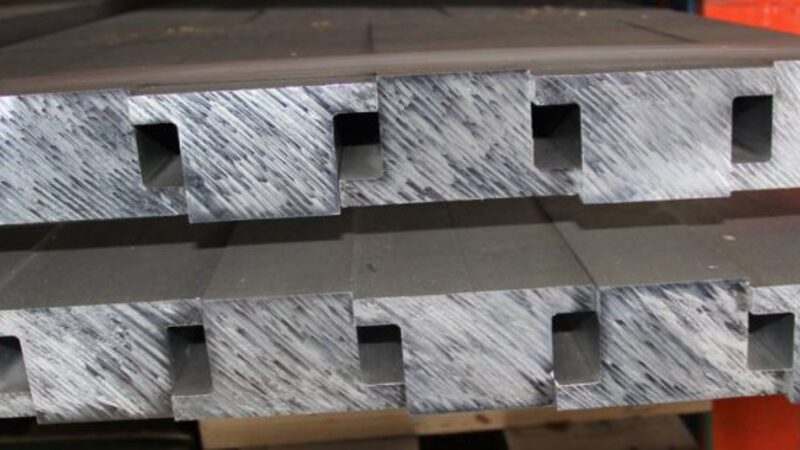

Precision Sawing Services

A very important value-added service to consider from any supplier of aluminum is precision sawing services. This allows the supplier to saw plate and bar to your requirements, helping to reduce freight cost and to also avoid waste at the facility or the job site.

Processing Requirements

In some cases, an Original Equipment Manufacturer or fabricator may require the aluminum go through a set of processes from grinding to machining or even finishing. By working with a supplier that can manage these tasks through outsourcing the work to trusted vendors, you can turn over the processing management to them, freeing up your company to focus on other aspects of the project.