Howard Precision Metals, is one of the leading aluminum supplier based out of Milwaukee, Wisconsin. One of the key products that finds application in several fields is the aluminum round bar. Aluminum bars are typically produced out of aluminum alloys. These bars are known for their excellent machinability, as well as workability. Since they are made up of aluminum, they also score high on the corrosion resistance front too.

Production Process

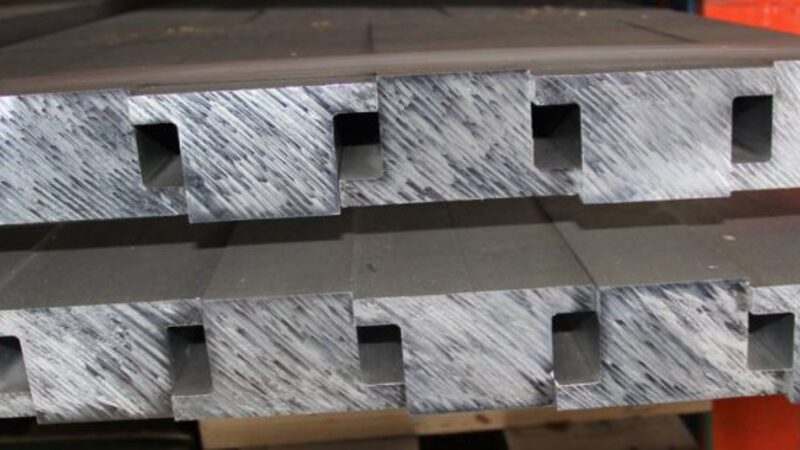

Aluminum bars are produced using different types of processes. They can be produced using coiling, rolling or extrusion methods. Bars and rods can also be directly drawn from molten aluminum too. The resultant aluminum bars can be machined for different applications. Some of the examples of products made out of aluminum bars and rods include bolts, nuts, nails, and screws.

Electricity Transmission

While Aluminum Round Bar finds applications in various industries, electrical transmission lines are one field where they brook no opposition. World over aluminum has the monopoly when it comes to delivering electrical power.

Aluminum wires are the most widely used for conducting electrical impulse in several types of industries. Aluminum is known to transmit twice the amount of electricity as copper and therefore a much more cost-effective option for utilities. Aluminum is also much easier to maintain as compared to other metals.

Corrosion Resistance

Another area where these round bars score high is in corrosion resistance. A naturally occurring protective oxide coating is what makes aluminum highly corrosion resistant. Over and above this surface treatment such as special paints or coats can further improve the corrosion resistant property of the round bars.

Recyclable Material

Adding to the sustainability quotient of these bars is the fact that aluminum is 100 percent recyclable. Even the recycling process is environment-friendly because as little as only about 10 percent of the energy that is required to produce the metal is required during the recycling process.