A range of different industries can benefit from the use of extruded aluminum shapes. These industries include construction and mining to just name a couple. A quality precision metals company that focuses on selling aluminum can enable customers to take advantage of precision parts and custom shapes to meet their project needs.

Extrusion Process

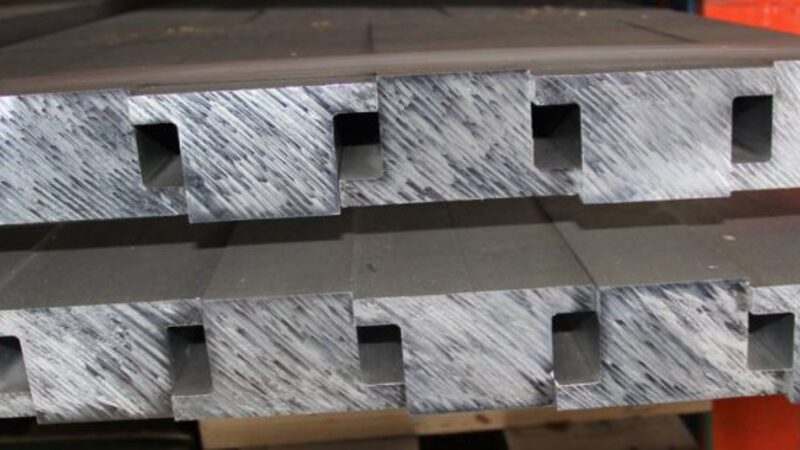

Extrusion process allows various components to be created through the transformation of aluminum alloy. This transformation process occurs as aluminum alloy billets are heated and become soft. In their softened state, they are force-fed, so to speak, through a ram or hydraulic press and then through specific steel dies that form the Parker shape that is needed. The extruded aluminum shape comes forth from the billet that moves through the die.

Shape Applications

The industries that can benefit from extruded aluminum shapes include mining, military, electronics, and automobile. The automobile industry is a heavy user of aluminum extrusions. These extrusions can be used for cooling and heating systems as well as vehicle radiators.

These extrusions can be used as components in a variety of different ways including for the use of engine blocks as well as truck, car, and boat chassis. Cooling and heating devices of computers and electronics field are also candidates for aluminum extrusions. An additional application includes thawing units for the pharmaceutical industry.

Benefits of Aluminum Extrusions

Aluminum conducts heat very efficiently. This is why it used often in cooling and heating systems as well as for devices in vehicles. The metal does not require special treatment in order to mitigate corrosion. Aluminum material has a natural resistance to the tear and wear afforded by aluminum oxide when it is bonded to its surface – it produces a shield against the outside elements.

Aluminum parts are able to resist the distortion that results from the building moving or swaying. The aluminum can absorb the impact efficiently and also retain its strength. It is a nonmagnetic material which makes it safe to use in areas where there are sensory magnetic devices or magnetic fields.

A reliable aluminum supplier can provide extruded aluminum shapes for customers according to the exact specifications given. As well, a company that uses precision sawing operations can help you achieve the precision you need in your project – this holds true for aluminum bar and played as well as extruded shapes.