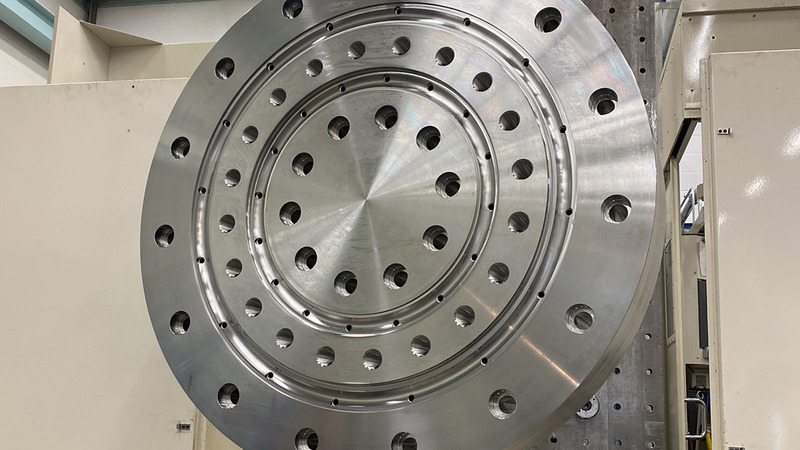

One of the difficulties many OEMs face is the challenge of machining large parts. Unfortunately, many machining companies take on large part CNC machining jobs without the experience and the systems needed to complete this task. This can lead to poor quality results, as well as the inability to meet exacting tolerances that are possible through the use of computer numerical control machining operations.

To ensure the machine shop has the ability to take on and successfully complete large part CNC machining jobs, there are a few steps the OEM can complete. These steps just take a few minutes, with information readily available on the website of any top contract manufacturer.

Equipment Capacity

A simple way to determine if a machining service has the capacity to handle large part CNC machining jobs is to look carefully at their equipment. For those with limited engineering and machining experience, it is still a simple process to check the size of the workpiece that can be machined or fabricated, given the specifics of the job.

It is also a good practice to speak directly with the machining service and to obtain confirmation of the ability to machine the parts required. This can also be helpful in understanding the options and pricing for the machining service.

The top companies provide this information in easy to read and understand format, allowing OEMs to quickly determine if the capacity meets the part size requirements. Keep in mind, the best machining companies, and particularly those working on large volume orders with other companies in your industry, typically have the capability and the capacity to produce large parts and high volume orders, making them a good match for any OEM.