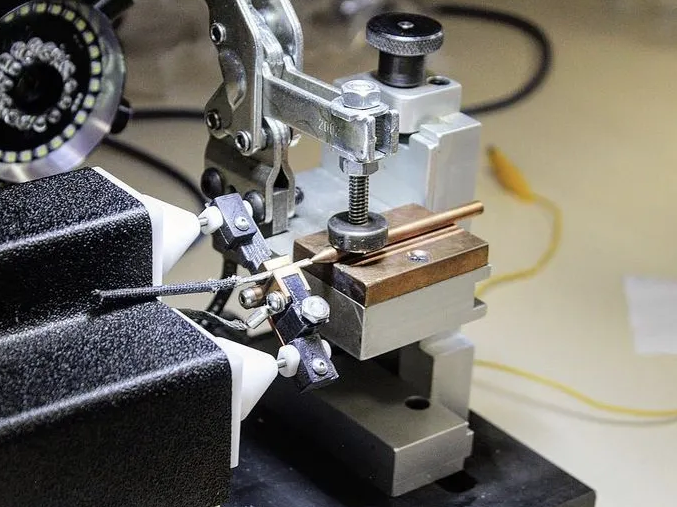

Capacitor discharge (CD) welding utilizes a time-tipped flanged fastener in the center of the flange. The capacitor discharge stud welder/operator places the weld stud either into a weld head or in a hand-held stud gun. The power supply consisting of several capacitors stores the electrical charge until the welder triggers its release, discharging it through the timing tip. This generates an electric arc. This, together with pneumatic force or spring pressure.

An electrical charge is stored in a bank of capacitors in the power supply, and upon triggering the welding unit, the electrical charge is discharged through the timing tip producing an electrical arc. Spring pressure or pneumatic force compels the weld stud into the hot, liquefied metal resulting in fusion. However, not all CD welding equipment is the same. Ensure the system your company orders features the characteristics its needs.

Essential Characteristics

When looking at available models and types of CD stud welders consider whether they possess any of the following essential characteristics:

- Durability

- Strength

- Speed

- Reliability

- Accuracy

- Ease of use

- Versatility – consider the specific thickness or thinness of metal the CD stud welder is capable of efficiently and precisely creating high-strength weld fasteners

- Problem-free – the CD process does not produce burn-through. Furthermore, it does not pierce the metal

It is also very important to consider the work environment and the characteristics of the workpiece. Moreover, never neglect to factor into the purchase decision such aspects as easy hook-up and portability. If portability is a requisite quality, be sure the equipment is lightweight and actually functionally portable.

Capacitor Discharge Stud Welder: Increasing Productivity

When companies install the equipment and employ a capacitor discharge stud welder, they are working to ensure improved productivity. With no predrilling requirements nor punching or riveting essential before performing the weld, it is easy to see how capacitor discharge stud welding can save a company time. Since time is money, the savings accrue.